The complete listing of Chinese prototype models is below. For model reviews, please scroll below the table or click here

The complete listing of Chinese prototype models is below. For model reviews, please scroll below the table or click here

The complete listing of Chinese prototype models is below. For model reviews, please scroll below the table or click here

The complete listing of Chinese prototype models is below. For model reviews, please scroll below the table or click here

JW4

1:87 Scale

Rating

9/10

JW4 Class Overhead Maintenance Diesel Railcar

N27

Production Summary

Prototype Information

The JW-4 Eagle Heavy Construction Machinery Co and is used for repairs and maintenance of electric overhead systems.

It shares the same platform and mechanics as the JY290 railcar, but equipped with a hydraulic powered platform for workers to access the electrical overhead system and, in some cases, a small crane. They have a B-B wheel arrangement and are powered by the Cummins NTC-290 supercharged diesel engine and RT-11509C transmission, enabling it to run at 100kph. They are found in most countries of the country, often with other maintenance machinery.

General Information

N27 released their second rail car about a year after the very successful JY290 rail car. A logical choice as much of the tooling could be shared with this project. They have produced an incredibly well detailed model of a fairly popular maintenance type with some very unique features to models of this type. It measures 149mms in length, 33mms wide (or 69mms with the small crane fully extended to the side) and 55mms high at its lowest position, 68mms high with the platform fully raised and another 4mms added on top of that if the handrails are in the raised position.

Packaging

N27's railcars come in excellent quality packaging. It comes in a solid 2 piece thick cardboard box with thick foam insert. The model is secured in a sleeved clear plastic clamshell. Inside the box is the instruction sheet.

Details

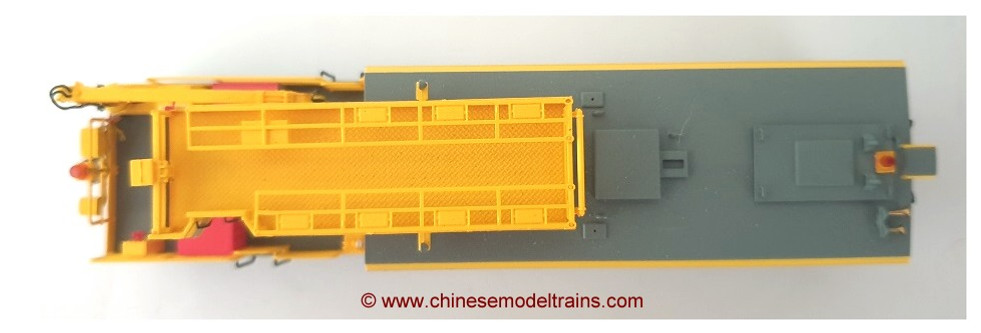

The model comes fully assembled and there are no add-on or optional parts included. It is exquisitely detailed, particularly on the rear half of the model with the platform. The under carriage is particularly well done with very realistic bogies and features the entire pneumatic system with air reservoirs and piping, an exhaust, color coded shock absorbers & roller bearing covers and drive shaft.

Most of the detail parts are plastic and they look amazing. The front handrails are wire and the air horns are brass. The feature separately applied uncoupling rods, air hoses with painted taps. The rear handrails appear to be made of plastic and carry the microscopic wires to the lights which can be seen exposed, but painted on the rear side. The paint work on these particular handrails appears a bit uneven, but not overly noticeable.

The main platform is telescopic and can be manually lifted. The handrails on the platform are in the folded down position, but can be removed and potentially glued in place for an upright appearance. Likewise, the small crane can be lifted and rotated, which looks extremely good with the hydraulic arm also functional. It goes without saying to handle these features with extreme care and take not e of the crane jib as it hooks into a guide on the floor. Again, this is a feature that must be activated manually. The control levers and crane angle guide are brilliantly executed.

The lettering is stunning, very sharp and lots of it. The tiny blue builders plates on the side are separate metal pieces and amongst some of the best I've seen to date. It has a plethora of warning labels such as no smoking, pinch points, electric shock etc and hazard striping on the ladder rungs.

Performance

My example runs very smoothly and has a good speed range. The electrical pickup is from a copper strip brush system which is pressed against the inside of each of the wheels. My example is fairly quiet and I think it will improve after a bit running. They are capable of pulling far more wagons than what they prototypically would. The motor has a single heavy brass fly wheels to further improve performance and reduce micro-dropouts.

Electronics

The JW-4's have an 8-pin plug for an 8-pin DCC decoder. The lights are good and include the twin globe headlights and white/red markers lights, all directional. The glow is bright, but a little on the yellow side for me. The lights on the platform are non-functional and there is no interior lighting. There is a toggle switch under the large roof panel to activate the lights and isolate the motor, a useful feature for DC operators. The roof mounted orange beacon is non-functional, but the one on the rear flashes in DC mode when the motor is isolated (not tested in DCC mode as of yet). It looks very realistic.

Disassembly

Access to the inside of the shell to install a decoder is via a series of clips on the inside of the body shell, plus one under near the center of the frame. This is a very tricky model to take apart, due chiefly to the huge amounts of detail parts hanging off the back.

Coupler Conversion

The plastic knuckle couplers can be replaced with Kadee #5, 58 (medium shank, scale heads) or 158's (medium shank, scale heads, whiskers). Both my examples shown in the photos are fitted with #158's. It is a very painless exercise requiring the removal of the pilot with a single screw gently remove it to prevent damage to the pressure-fit lug. The second screw can then be removed to remove the coupler box plate.